UHV Power Transmission and Power Electronics

XJ Group has achieved a series of achievements with independent intellectual property rights in UHV DC transmission control and protection systems, converter valve equipment, DC field equipment, and UHV AC control protection and monitoring systems, and its technical level and industry status are at the world's leading level. , Leading the development of the world's UHV DC equipment technology and engineering technology.

- Independently developed the world's first ±800kV/3125A optically controlled converter valve assembly, the world's first ±800kV/4000A electronically controlled converter valve assembly, and the world's first largest delivery capacity and highest voltage level Back-to-back DC engineering converter valve.

- Independently developed the world's first: ±800kV, 6.4 million kilowatt DC transmission control and protection system, and successfully applied to Yunnan-Guangzhou, Sichuan-Shanghai, Nuozhadu-Jiangmen and other ±800kV UHV DC transmission projects. Multiple ±800kV UHV DC transmission projects in Shanghai, Nuozhadu-Jiangmen, etc.

- Advanced research and development of the world’s largest operating current ±1100kV UHV DC transmission converter valve, ±320kV flexible DC transmission converter valve, UHV DC field equipment integration and other products and technologies have filled the global gap and applied them on a large scale "Jinping-Sunan, Nuozhadu, Xiluodu" and other UHV DC transmission projects.

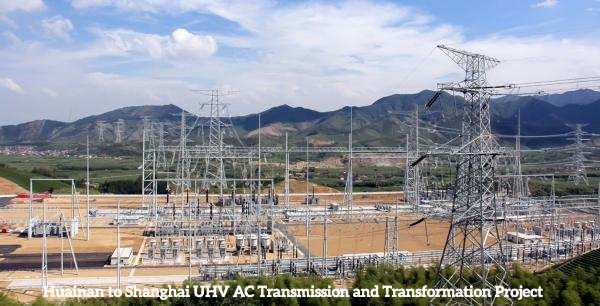

- Provided complete sets of equipment and technical services such as substation monitoring system and series protection for 1000kV Jindongnan-Nanyang-Jingmen and 1000kV Huainan-Shanghai UHV AC transmission demonstration projects, supporting the further development and large-scale application of China's UHV AC transmission technology .